What are things prime mover drivers should take note of when operating their vehicles? Use our inspection checklist below to ensure that your prime movers, trailers and containers are in good working condition!

Container Inspection

Each time a container exchanges hands, the liability is transferred from one party to another. It is therefore important for drivers to inspect the condition of the container and report any damages, if found.

1. Empty Containers

When collecting empty containers from customers, depots or ports, drivers must ensure that the container’s interior is free of debris, dry and odor free. Drivers should also ensure any previous hazardous labels have been removed.

When checking if the container is fit for loading or empty returning, drivers should also pay particular attention to the following:

- All doors and door-catches should be in good working order and closed.

- The floor should be clean with no unusual internal protrusions and all residues and debris removed.

- The roof should have no apparent holes.

- The identification plate should be readable and valid.

- If using a 3rd party owned or shared chassis the tires, should be checked for visible damage or leaks.

2. Loaded Containers

When collecting loaded general purpose (GP) containers from customers or ports, the driver should pay particular attention to the following:

- All doors should be locked properly.

- Seals are attached and verified.

- No visible damage which might endanger the cargo.

- The identification plate should be readable and valid.

- Tires should be checked for visible damage or leaks.

3. Loaded Refrigerated Containers (Reefers)

When collecting loaded reefers from customers or ports, drivers should pay particular attention to the following:

- All doors should be locked properly.

- Genset should be operational.

- Seals are attached.

- No visible damage which might endanger the cargo.

- The identification plate should be readable and valid.

- Tires should be checked for visible damage or leaks.

When collecting loaded refrigerated containers (reefers) for temperature-controlled transportation, the driver should ensure that the temperature remains at the set temperature as specified in the documentation and/or work order at all times. The fuel level of the genset should also be checked prior to departing the collection site.

4. Containers Seals

Prior to leaving from port/terminal or customer premise with the loaded container, the driver should check the seal number(s) to ensure it is intact and matches the number(s) on the delivery instruction, documentation and/or work order.

Affixed seal numbers are to be noted down on the proper documentation and need to be signed off prior to departure.

If there is any mismatch with seal numbers, either on delivery instruction, documentation and/or work order, the container should not be moved, and the customer must be notified immediately.

No container seal should be affixed or removed unless it is under the supervision and presence of the customer, the Customs officer or port official.

5. Hazardous Cargo

All drivers transporting hazardous cargo MUST be trained in the relevant Dangerous Goods regulations, enabling them to move the hazardous cargo required. They must also carry a valid local training certificate to verify this at all times. Drivers who are not appropriately trained should not be scheduled for hazardous transport.

When hazardous cargo is involved, each vehicle is to carry a toolkit in accordance with local regulations. The following are examples of items required in the toolkit:

- Hard hat

- Goggles

- Gloves

- First aid kit

- Eye wash (with valid date)

- Safety footwear

- High visibility jacket or vest

- Torch

- Suitable and properly charged fire extinguishers (with valid date)

When hazardous cargo is being moved (import-export), the driver must check that the hazardous placards (in accordance with the declaration on the dangerous goods note) have been placed on all 4 sides of the container. He/she should also obtain the appropriate Dangerous Goods Declaration and Dangerous Goods Standard Shipping Note, correctly filled out by the customer. In the event that the Dangerous Goods Declaration, Dangerous Good Note and hazardous placards are not available, this must be reported to the customer to obtain instruction.

No container should be moved unless both the documentation and placards are available to accompany the driver/vehicle. The vehicle must be parked until the situation is resolved.

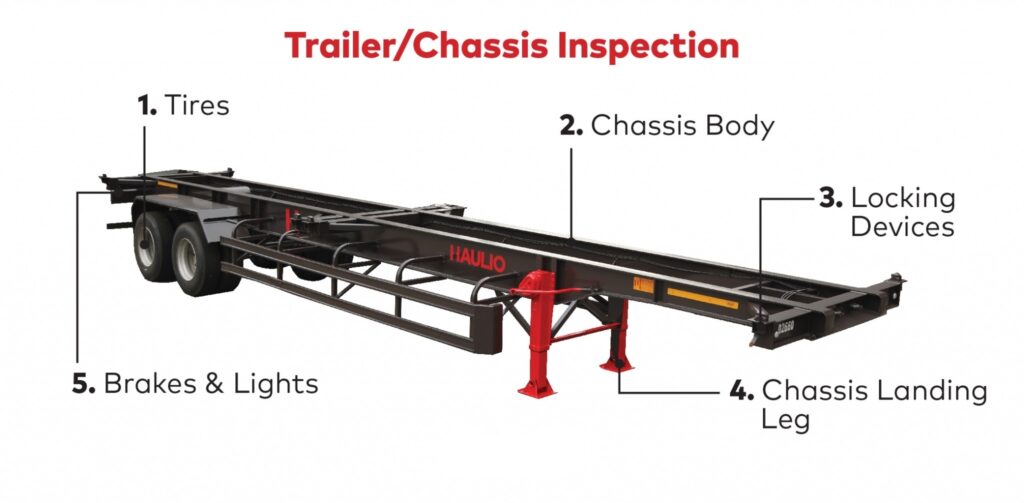

Chassis/Trailer Inspection

Everytime a chassis is picked up or parked, drivers should perform a quick check on the chassis/trailer.

1. Tires

- Tires are well inflated.

- Tires are choked after parking or before mounting.

- Tires are unchoked before driving off.

2) Chassis Body

- There are no noticeable damages on the chassis body.

- The chassis collected is suitable for the intended payload of the container VGM.

3) Locking Devices

- Inspect all locking and coupling devices and check that there are no ineffective parts.

- There should not be any excessively worn, bent or broken missing parts.

4) Chassis Landing Leg

- Chassis Landing Leg is not damaged.

- Landing Gear is working.

- The position of the Chassis Landing Leg position is correct before and after mounting/dismounting.

5) Brakes & Lights

- All Brakes and Lights functions are working.

- Connectors are secured properly.

Prime Mover Inspection

1. Check that fluid levels are within manufacturers’ specifications:

- Engine oil level

- Brake fluid level

- Radiator fluid level

- Battery water level

- Window washer water level

- Fuel level

- Windscreen washer level

2. Check that lights are in working condition:

Headlights (high beam)

Headlights (low beam)

Licence plate

Reverse

Cabin interior

Brake indicator

Hazard

Indicators turn signals

3. Ensure that the following are adjusted to suit driver’s view:

Driver seat

Rear view mirror

Side mirrors

Blindspot mirrors

4. Ensure that the pedals are working:

Foot brake holds, stops vehicle smoothly.

Parking brake holds against slight acceleration.

Clutch and gearshift shift smoothly without jerking.

5. Ensure that the tyres are in good condition:

Tyres are inflated and free of excessive wear or damage.

Nuts are tight.

Adequate thread.

Check spare tyre (i.e. inflated and no visible cracks).

6. Ensure that there are Safety Equipment:

First Aid Kit is stocked with no expired items.

Fire Extinguisher is available and not expired.

Personal Protective Equipment is available

7. Ensure that the following are in working condition:

Seat belts are working and free of damage.

Mirrors are clean and no visible damages.

Doors and door locks operate correctly.

Dash control panel are fully operational (i.e., all lights and dashes).

Steering wheel moves smoothly.

Horn is loud and clear.

Vehicle reverse alarm (if fitted) is working.

Hydraulic systems are operating smoothly (i.e., no visible leaks and systems).

All loads (if any) are secured.

Reverse warning buzzer is working.